Products

-

Vertical FRP Tank

-

FRP Liquid Alkali Storage Tank

-

FRP Scrubber Tower

-

FRP on-site winding tanks

-

Scrubbing tower

-

FRP anode tubes

-

Air cooled heat exchanger

-

PPH Agitator tank

-

FRP pipes

-

Circular cooling towers

-

FRP bromine towers

-

Evaporative condenser

-

Potassium Sulfate EPC Project

-

FRP chimneys

-

FRP Hydrochloric Acid Tank

-

FRP Cooling Tower

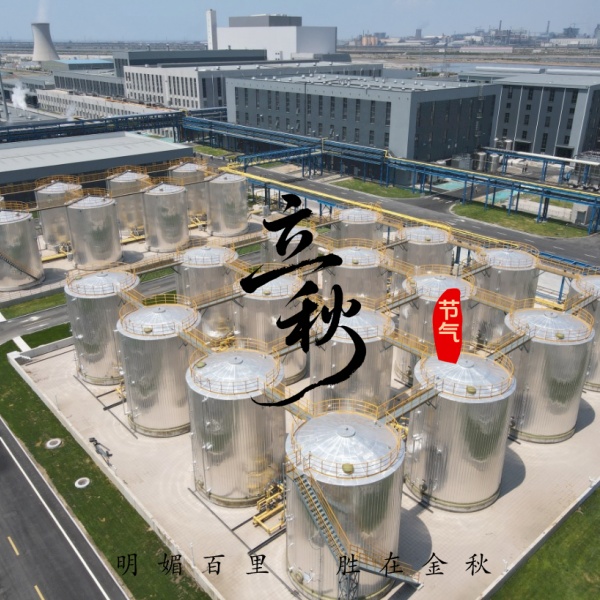

PPH storage tank

The main processes of PPH equipment manufacture include tank extrusion winding,external welding,internal seam welding,nozzle installation, etc..High temperature hot melt spiral extrusion winding technology is adopted in the manufacture of cylinder body, which can improve mechanical strength, safety and reliability of products. PPH equipment with good acid resistance, alkali performance is widely used in chemical, new energy,food and other industries.

Description

marker

The main processes of PPH equipment manufacture include tank extrusion winding,external welding,internal seam welding,nozzle installation, etc..High temperature hot melt spiral extrusion winding technology is adopted in the manufacture of cylinder body, which can improve mechanical strength, safety and reliability of products. PPH equipment with good acid resistance, alkali performance is widely used in chemical, new energy,food and other industries.

Because PPH equipment has recycling value compared with FRP, for the future waste environmental treatment more convenient, by more and more customers use a lot.

The shell of PPH storage tank has good integrality, no weld, no leakage, strong impact resistance, high tensile strength, good anti-oxidation and anti-aging performance.

Due to the excellent performance of linear low density polyethylene (LLDPE) and the special structure of PPH tank, the service life can be over 15 years.

PPH tank has the inside and outside anti-corrosion characteristics, can be placed in high corrosion environment.

PPH winding storage tank is also polypropylene storage tank, polypropylene can be divided into many kinds, PPH is only one of them.

No matter from strength, acid and alkali resistance, aging resistance or appearance, PPH tanks have great advantages.