Itroduction of new German Mannheim process for potassium sulfate production

2025-07-31

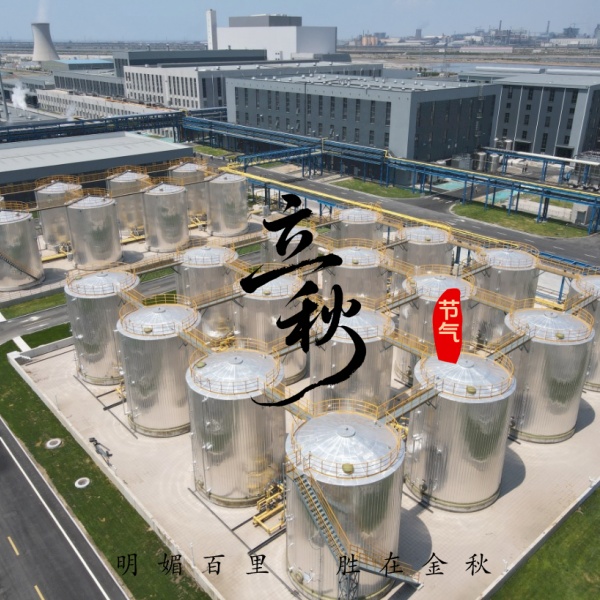

Based on the original German Mannheim process for potassium sulfate production, we have conducted in-depth research into its working principles through over a decade of equipment manufacturing and production practice. By optimizing the reactor structure and upgrading materials, we have successfully resolved corrosion and high-temperature resistance challenges in furnace components. Furthermore, the hydrogen chloride absorption section employs innovative materials and advanced processes to ensure uniform heating and complete reaction of materials, significantly improving absorption efficiency. Practical production results demonstrate that this enhanced process not only achieves full compliance with environmental standards for waste emissions, but also delivers remarkable economic and environmental benefits for users:a 60% reduction in equipment maintenance costs, 20% decrease in energy consumption, and approximately 20% increase in unit productivity.

The Mannheim reaction furnace developed by our company adopts new refractory materials, improves the combination method of brick shapes, uses special mortar, and has a double-flue structure. By increasing the thermal conductivity of silicon carbide, it greatly reduces energy consumption and improves production capacity.

According to professional calculations, each of our production lines can generate an annual direct economic value increment exceeding RMB 2 million for client enterprises. Furthermore, our company has its own physical manufacturing facility where the core equipment of these production lines is fabricated, ensuring fully guaranteed quality. In contrast, other suppliers typically procure their equipment from the open market, which cannot provide equivalent quality assurance.